Industry OverView

The printing, converting and packaging industry has been in existence for a long while now. Some estimates put the figure at 2.5 lakh units* on an All-India basis. Making it one of the largest in the world. 2022 saw 413 Bn** packaging units being fed in to the market, translating to revenue of ~ 79.1 Bn USD** with a CAGR of 12.6%.

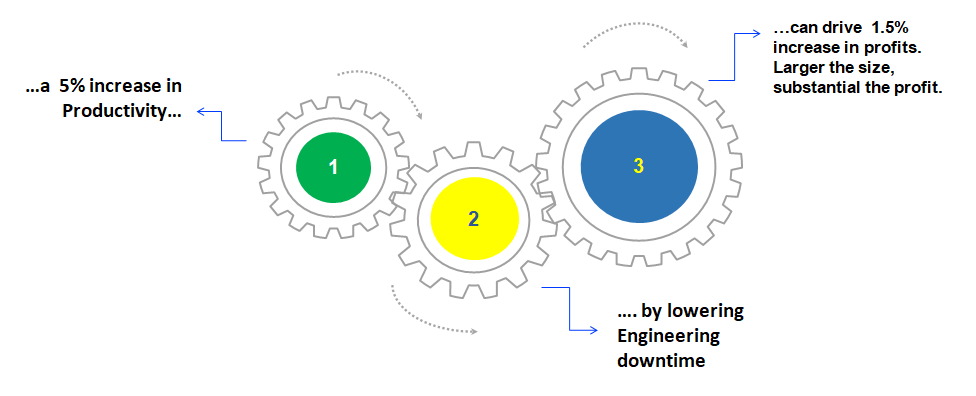

World class technology and equipment form the cornerstone, on which the industry depends, for their revenue. Added on to this is better capacity utilization.

** www.aifmp.org** www.mordorintelligence.com/industry-reports/packaging-industry-in-india

Industry Characteristics

Printing, converting and packaging is a capital-intensive industry with high asset turnover ratio.

Industry Plagued by:

- Low-capacity utilisation

- Low productivity

- High machine downtime

- Low EBIDTA

This is further intensified with delayed collections from clients accentuating an acute working capital issue. Questions the industry is confronted with today is:

- Should capex be deferred?

- How do I enhancesales, to better total margins?

- How do I increase profitability?

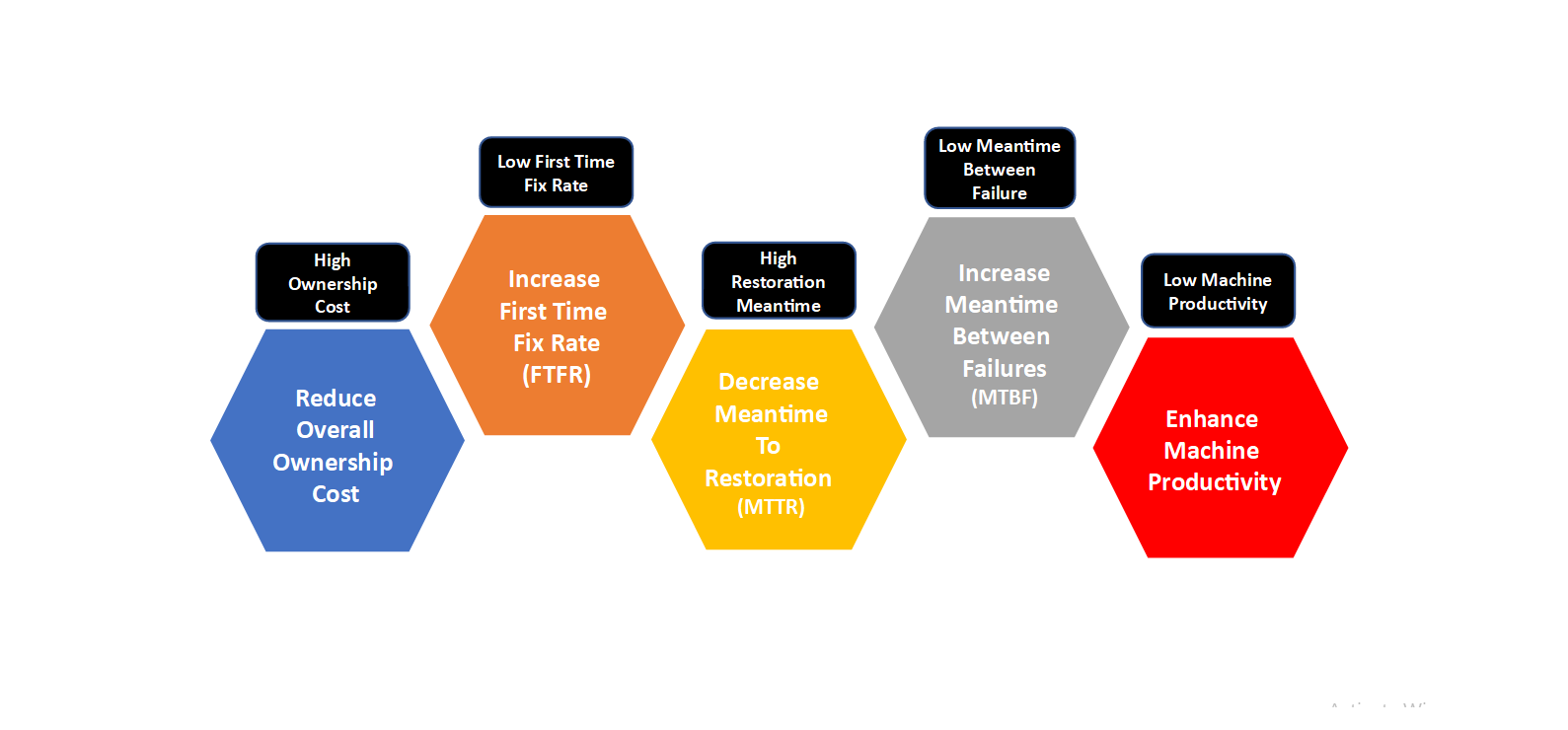

Optimization, better capacity utilization are all important factors for the health of the industry. In order to stay competitive within the industry, it needs to have

- Higher machine uptime

- Waste reduction mechanism

- Reduction quality complaints

- Commit themselves to enhanced deliveries

Cloverleaf Global Solutions Private Limited has been formed just for this purpose. It brings in industry 4.0 standards to help improve productivity of your printing, converting and packaging assets. Be it of any make – Indian or International.

Industry Significance

Industry Relevance Printing, Converting and Packaging

Functionality Drivers

Demand Drivers

E-commerce

Pharma

FMCG

FMCG

Durables

Our Story

Founded by industry veterans, who have experienced live situations, Cloverleaf aims to introduce

Industry 4.0 Standards for the printing, converting and packaging industry while further extending

plans to help other industries, which face similar problems.

They are :

- Textile & Garments

- Metal Processing & Fabrication

- Food Processing

- Dairy & Beverages

- Leather & Shoes

- Agri Sector - Jute & Rice Mills

- Earth Mining

At Cloverleaf our service offerings will leverage such standards and learnings to improve machine performance, productivity and run times. In turn enhancing returns for machine owners. Widely said interchangeably as the Fourth Industrial Revolution, Industry 4.0 at its core refers to the “smart” and connected production systems that are designed to sense, predict, and interact with the physical world, so as to make decisions and take actions that support production processes. Anticipating faults and foreseeing machine conditions, remotely by digitally wiring up a system to help take just-in-time actions. This is what Cloverleaf is set to follow.

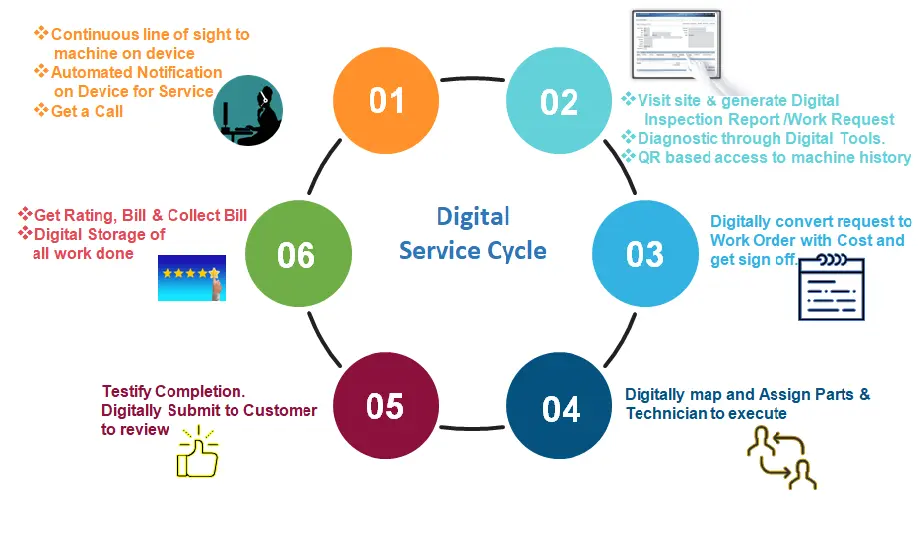

Our service Cycle

Vision

WE AIM TO DEFINE THE FUTURE OF MACHINE SERVICE.

Mission

-

01

CloverLeaf

Aims to make machine owners,

-

02

more productive & profitable,

-

03

by creating efficiency in the production value chain,

-

04

creating winning standards along the value chain,

-

05

from a single window by leveraging digital technology.

-

06

We aim to make machine maintainance hassle free

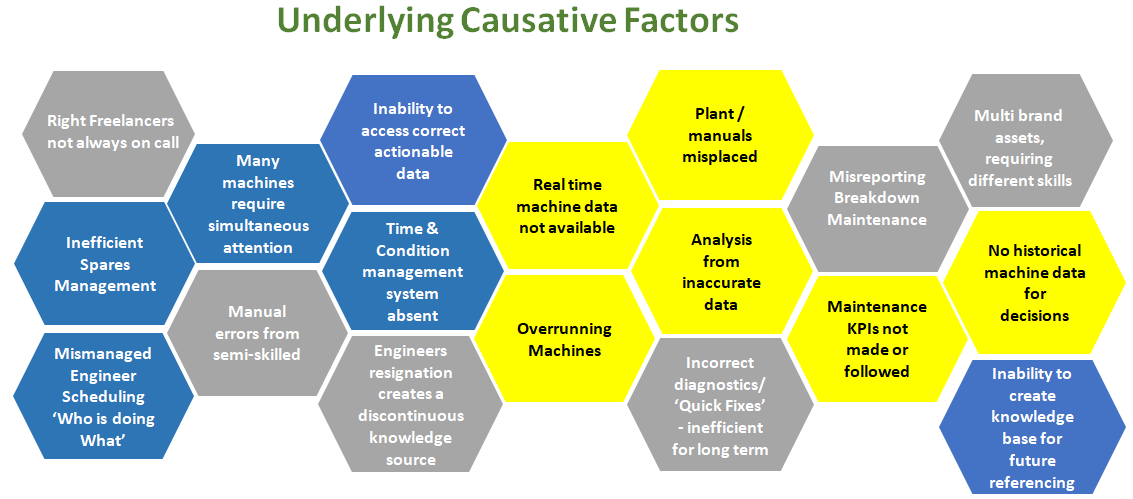

What are we solving for

How

- We will do this by creating a customised digital workflow, to capture pecularities of each customer and their shop floor.

- This digital work flow will create a line of sight and map machine, material & manpower, like an ‘Eye in the Sky’.

- This will enable a seamless, hassle free ‘Just in time’ service of your printing, converting and packaging assets.

- These data driven dashboards will reflect machine health & records and help me quick, informed decisions.

- In addition, a ‘Marketplace’ model for spares, consumables, engineers will provide transparency.

- It will introduce ‘Industry 4.0’ standards to the printing, converting and packaging industry sector.